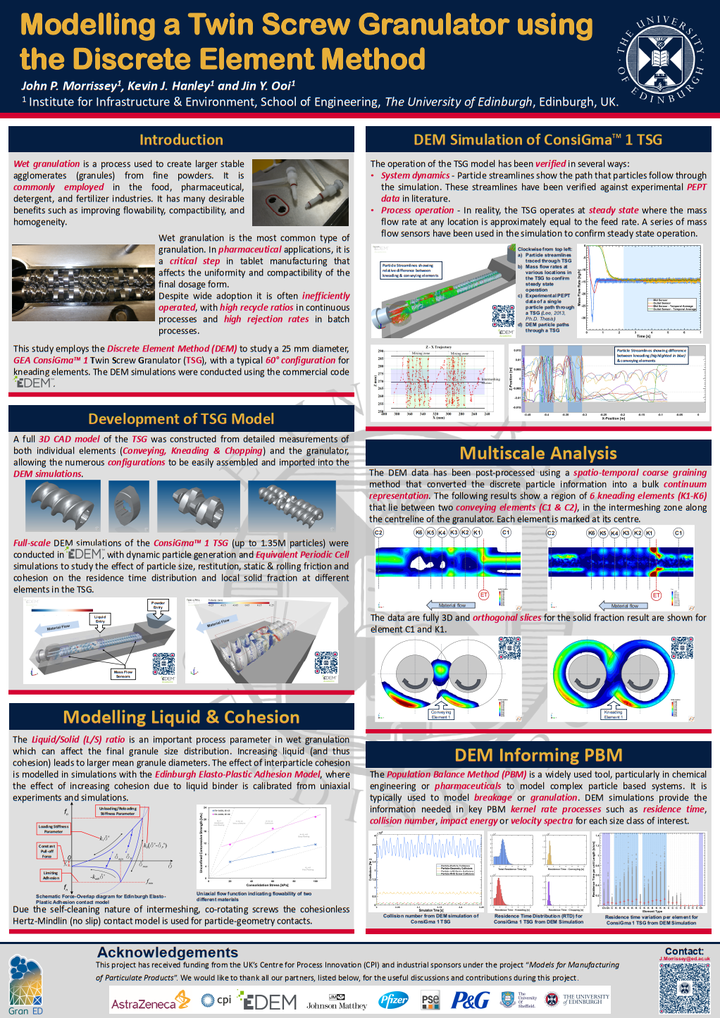

This study employs the Discrete Element Method (DEM) to study a 25 mm diameter, GEA ConsiGma™ 1 Twin Screw Granulator (TSG), with a typical 60°configuration for kneading elements. The DEM simulations were conducted using the commercial code EDEM. Wet granulation is a process used to create larger stable agglomerates (granules) from fine powders. It is commonly employed in the food, pharmaceutical, detergent, and fertilizer industries. It has many desirable benefits such as improving flowability, compactibility, and homogeneity. Wet granulation is the most common type of granulation.

In pharmaceutical applications, it is a critical step in tablet manufacturing that affects the uniformity and compactibility of the final dosage form. Despite wide adoption it is often inefficiently operated, with high recycle ratios in continuous processes and high rejection rates in batch processes. A full 3D CAD model of the TSG was constructed from detailed measurements of both individual elements (Conveying, Kneading & Chopping) and the granulator, allowing the numerous configurations to be easily assembled and imported into the DEM simulations.